1999-2006 Chevrolet Silverado / GMC Sierra 1500 Ladder / Traction Bars

1999–2006 Chevy Silverado / GMC Sierra 1500 Ladder/Traction Bars

Upgrade your 1999–2006 Chevy Silverado or GMC Sierra 1500 with heavy-duty ladder bars engineered for maximum traction and axle control. Whether you’re towing, hauling, or launching hard off the line, these bars are designed to eliminate wheel hop and protect your leaf springs under load — without compromising ride quality. Fits nearly all lift heights, making it a versatile solution for stock or modified setups.

🔰 Key Features

🟩 Eliminates Axle Wrap & Wheel Hop – Keep your rear end planted under acceleration for smoother launches and better traction

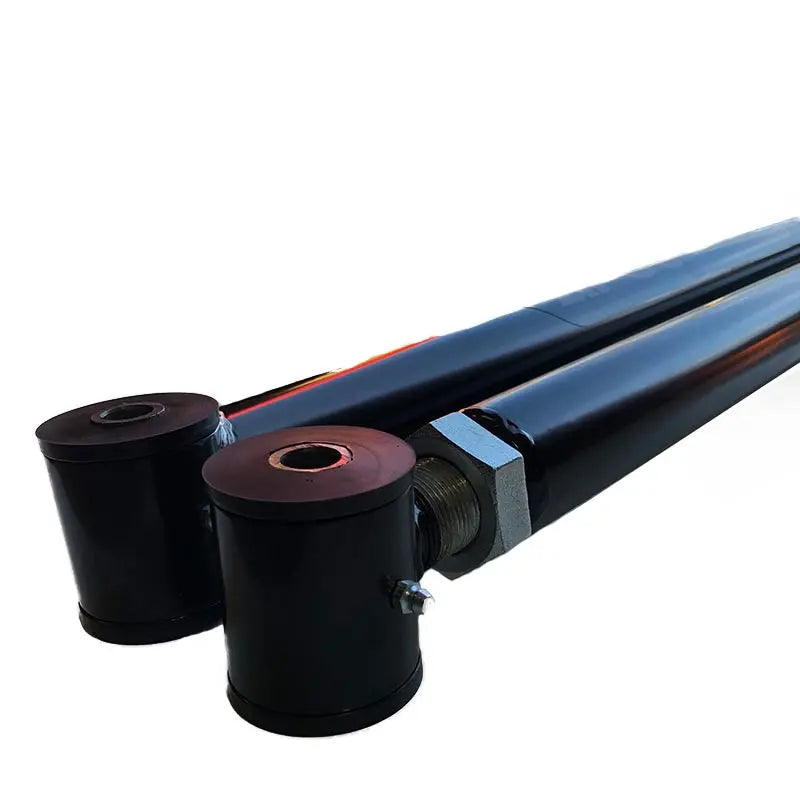

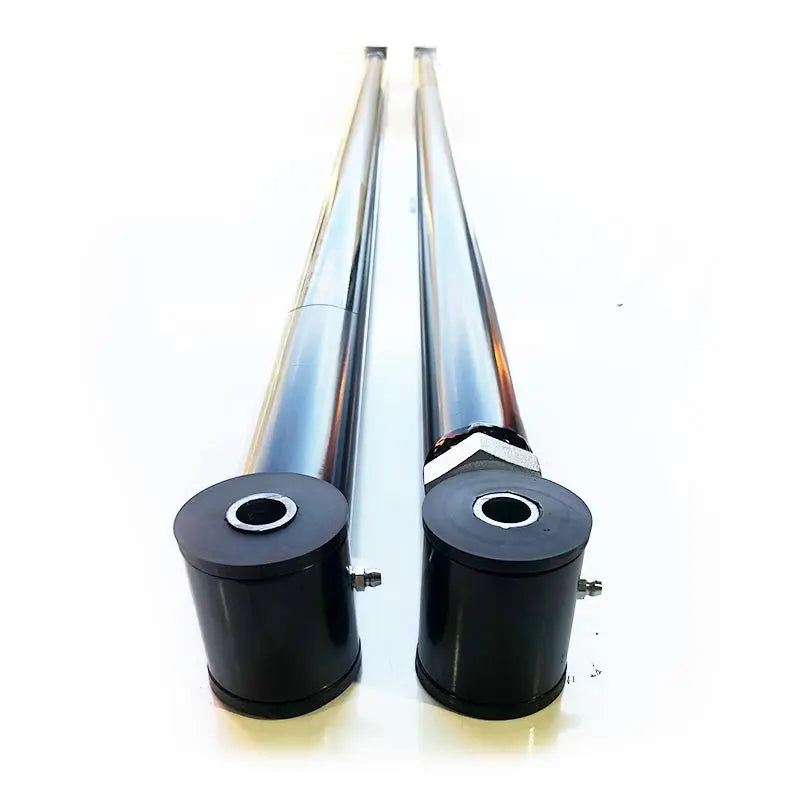

🟩 Heavy-Duty Steel Construction – Built for serious strength and long-term durability

🟩 Direct Bolt-On Design – No cutting or welding required; mounts securely to factory leaf spring perches and frame

🟩 High-Clearance Profile – Tucks neatly under the truck for optimal ground clearance and aggressive styling

🟩 Durable Polyurethane Bushings – Noise-free, low-maintenance operation with excellent vibration dampening

🟩 Black Powder-Coated Finish – Long-lasting corrosion resistance and stealthy appearance

🟩 🇺🇸 100% American Made in Tennessee – Fabricated, welded, and finished entirely in-house for unmatched quality

🧰 Installation

Fitment: 1999–2006 Chevrolet Silverado 1500 & GMC Sierra 1500 (2WD & 4WD)

Lift Compatibility: Works with most lift kits and stock-height setups

Install Time: ~1–2 hours with standard tools

No Welding Required – Fully bolt-on application

⚠️ Reuses factory U-bolts or aftermarket hardware — If your U-bolts are worn or too short, replacements may be required. Always check fitment before final torque.

📦 What’s Included

-

(1 Pair) Ladder/traction bars

-

Mounting brackets and hardware

-

Installation instructions

🚘 Application Notes

-

Designed for leaf spring rear suspension trucks only

-

Not compatible with airbag suspension conversions

-

For 1500 models only — not for 2500HD/3500 trucks

Built Right. Backed Right.

Our crew’s on call Monday–Friday, 9–5 EST. Hit us up at 865-983-5004 — real support, done right.

Product specifications

Yes – Fits Nearly All Lift Heights

PTMEG Polyurethane 91 Durometer

Adjustable from shortest length up to +2.5"

Powder Coated Satin Black (Bare Metal available if selected)

2" Outer Diameter (OD), 3/16" Wall Thickness

Built to Control Torque

Apoc Industries ladder bars deliver relentless traction and control, locking down your rear suspension under hard launches, towing, or off-road abuse. Precision-welded, made in the USA, and ready to dominate whatever you throw at them

Bolt-On U-Bolt Mounts for Ladder Bars

Apoc U-Bolt Mounts are designed for setups where the U-bolts face downward, with the nuts positioned underneath the axle. These mounts install between the original axle mount bracket and the U-bolt nuts, providing a secure and convenient mounting point for ladder bars without requiring additional modifications.

Frame-Mounted. Torque-Tested.

The Apoc Bolt-On Frame Mount is built for serious strength and easy installation. Designed to work with our traction bar kits, it bolts directly to the truck’s frame—no welding required. Precision-cut from thick-gauge steel and powder-coated for durability, this mount provides a rock-solid connection point that holds up under heavy torque, towing, and hard launches.

Lifetime Warranty Polyurethane Bushings

Built to Last, Easy to Rebuild

Apoc Industries' high-performance polyurethane bushings are backed by a lifetime warranty and engineered for durability you can count on. Easily rebuildable with basic tools, they deliver a firm, responsive ride without the hassle—made for daily drivers and built for the long haul.

Before

After

Ladder Bar Kits

Built to Control Torque. Eliminate Wheel Hop.

Complete Kit – Ready to Install:

The Apoc Traction Bar Kit for Ram trucks includes everything you need for a complete install: two heavy-duty traction bars, frame-side brackets, axle-side brackets, and all required grade 8 hardware. Designed to control axle wrap and improve traction under load, this kit is built to handle serious torque while keeping your suspension tight and your rear end planted.

Preload It. Fine-Tune It.

The traction bars are fully adjustable, allowing you to fine-tune the setup without relocating the frame mounts when changing lift heights. You can also preload the bars to tighten up suspension response and reduce unwanted movement under load—giving you more control, less wheel hop, and a smoother, more planted ride.

Premium Bushings – Built for Life:

Apoc Industries backs our bushings with a Lifetime Warranty for lasting confidence. We use only the highest quality polyurethane (PTMEG-based) in all Apoc products.

PTMEG polyurethane offers superior articulation and a firmer, more responsive feel — without the harshness commonly found in solid joints like heims or flex joints.

These bushings are ideal for daily driving while providing excellent durability and performance for moderate off-road use.

100%

Red, White & Built Right

FAQ'S

Traction Bars

Our customer support is available Monday to Friday: 9am-5pm EST. 865-983-5004

A: Traction bars prevent axle wrap—when your rear axle twists under load—which can cause wheel hop, vibration, and premature wear on driveline components. Apoc traction bars keep the rear end planted under hard acceleration, towing, or off-road use.

A: If your Ram is lifted or sees heavy towing, yes. Even on daily drivers, traction bars help reduce rear-end movement, improve driveline alignment, and extend the life of suspension and axle components. If you're running taller-than-stock lift blocks, traction bars are strongly recommended to prevent axle wrap and maintain stability under load or acceleration.

A: Yes. The kit is designed for a straightforward, bolt-on install using basic hand tools. The frame-side brackets do require drilling, but no welding is needed. If you’re mechanically inclined, you can knock it out in a few hours at home. Prefer a shop? No problem—it’s installer-friendly either way.

For PTMEG (polytetramethylene ether glycol) polyurethane bushings, the best grease is a silicone-based lubricant with PTFE (polytetrafluoroethylene) additives. Here’s why and what to consider:

Why Silicone-Based with PTFE?

: PTMEG polyurethane is resistant to petroleum-based products, but silicone-based grease is preferred as it won’t degrade the material and is explicitly recommended for polyurethane bushings.Tackiness

: PTFE additives lower the coefficient of friction and are waterproof, ensuring long-lasting lubrication and quiet operation.

: Silicone-based grease repels water, protecting bushings from corrosion and maintaining performance in wet conditions.